Isishwankathelo seSidibanisi soMbane oPhezulu

Izihlanganisi ezine-voltage ephezulu, ezaziwa ngokuba ziziqhagamshelo ezinombane ophezulu, luhlobo lwesinxibelelanisi semoto. Ngokuqhelekileyo zibhekisa kwizihlanganisi ezinombane osebenzayo ngaphezulu kwe-60V kwaye zinoxanduva lokuhambisa imisinga emikhulu.

Izixhumi ze-high-voltage zisetyenziswa kakhulu kwiisekethe eziphezulu kunye neziphezulu zangoku zezithuthi zombane. Basebenza ngeengcingo ukuthutha amandla ebhetri ipakethi ngokusebenzisa iisekethe zombane ezahlukeneyo ukuya kumacandelo ahlukeneyo kwinkqubo yesithuthi, ezinje ngeepakethi zebhetri, abalawuli beemoto, kunye nabaguquli beDCDC. izinto ezinombane ophezulu ezifana neziguquli kunye neetshaja.

Okwangoku, kukho iinkqubo ezintathu eziphambili zemigangatho ye-high-voltage connectors, ezizezi LV, iplagi esemgangathweni ye-USCAR, kunye neplagi yaseJapan esemgangathweni. Phakathi kwezi plug-ins zintathu, i-LV ngoku inokusasazwa okukhulu kwimarike yasekhaya kunye neyona migangatho yenkqubo epheleleyo.

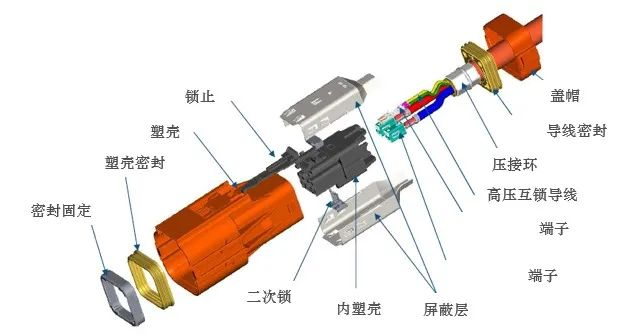

Umzobo wenkqubo yendibano yesidibanisi sombane ophezulu

Ulwakhiwo olusisiseko lwesinxibelelanisi samandla ombane aphezulu

Izihlanganisi ezine-voltage eziphakamileyo zenziwa ikakhulu ziziseko ezine ezisisiseko, ezizezi, ii-contacters, ii-insulators, amaqokobhe eplastiki kunye nezixhobo.

(1) Abafowunelwa: iindawo eziphambili ezigqibezela uqhagamshelo lombane, ezizezi, iitheminali zamadoda nemazi, iingcongolo, njl.njl.;

(2) I-Insulator: ixhasa abafowunelwa kwaye iqinisekisa ukugquma phakathi kwabafowunelwa, oko kukuthi, igobolondo leplastiki yangaphakathi;

(3) Igobolondo lePlastiki: Igobolondo yesiqhagamshelo iqinisekisa ukulungelelaniswa kwekhonkco kwaye ikhusela yonke ikhonkco, oko kukuthi, igobolondo leplastiki yangaphandle;

(4) Izixhobo: kubandakanywa izincedisi zesakhiwo kunye nezixhobo zofakelo, ezizezi izikhonkwane zokubeka, izikhonkwane zesikhokelo, amakhonkco okudibanisa, amakhonkco okutywina, iilever ezijikelezayo, izakhiwo zokutshixa, njl.

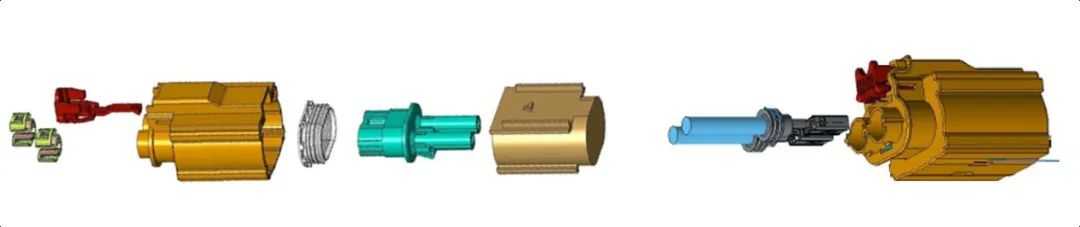

Isidibanisi sombane ophezulu sigqabhukile umbono

Ukuhlelwa kwezihlanganisi zombane ophezulu

Izihlanganisi zombane ophezulu zinokwahlulwa ngeendlela ezininzi. Ingaba ikhonkco inomsebenzi wokukhusela, inani lezikhonkwane zokudibanisa, njl.

1.Ukuba kukho okanye akukho ukukhusela

Iziqhagamshelo ze-voltage eziphezulu zohlulwe zibe ziziqhagamshelo ezingakhuselekanga kunye neziqhagamshelo ezikhuselweyo ngokubhekiselele ekubeni zinemisebenzi yokukhusela.

Izihlanganisi ezingakhuselekanga zinesakhiwo esilula, akukho msebenzi wokukhusela, kunye neendleko eziphantsi. Isetyenziswa kwiindawo ezingadingi kukhuselwa, ezifana nezixhobo zombane ezigqunywe ngeekesi zentsimbi ezifana neesekethi zokutshaja, izinto zangaphakathi zeebhetri, kunye nolawulo lwangaphakathi.

Imizekelo yeziqhagamshelo ezingenamaleko okhuselayo kunye noyilo lwe-high-voltage interlock

Izihlanganisi ezikhuselweyo zinezakhiwo ezintsonkothileyo, iimfuno zokukhusela, kunye neendleko eziphezulu. Ilungele iindawo apho kufuneka umsebenzi wokhuselo, njengalapho umphandle wezixhobo zombane uqhagamshelwe kwiintambo zombane ezinombane ophezulu.

Isidibanisi esinekhaka kunye noyilo lweHVIL Umzekelo

2. Inani leeplagi

Izihlanganisi ze-high-voltage zahlulwe ngokwenani lamazibuko oqhagamshelwano (i-PIN). Okwangoku, ezona zisetyenziswa ngokuqhelekileyo ziyi-1P ikhonkco, i-2P ikhonkco kunye ne-3P yokudibanisa.

Isidibanisi se-1P sinesakhiwo esilula kunye neendleko eziphantsi. Ihlangabezana neemfuno zokukhusela kunye nokukhusela amanzi kwiinkqubo eziphezulu ze-voltage, kodwa inkqubo yendibano iyinkimbinkimbi kwaye i-rework operability impofu. Isetyenziswa ngokubanzi kwiipakethi zebhetri kunye neenjini.

Izixhumi ze-2P kunye ne-3P zinezakhiwo ezinzima kunye neendleko eziphezulu. Ihlangabezana neemfuno zokukhusela kunye nokukhusela amanzi kwiinkqubo eziphezulu ze-voltage kwaye inokugcinwa kakuhle. Ngokuqhelekileyo isetyenziselwa igalelo kunye nemveliso ye-DC, efana neepakethi zebhetri eziphezulu zombane, iitheminali zokulawula, iitheminali ze-DC zeshaja, njl.

Umzekelo we-1P/2P/3P wombane ophezulu wombane

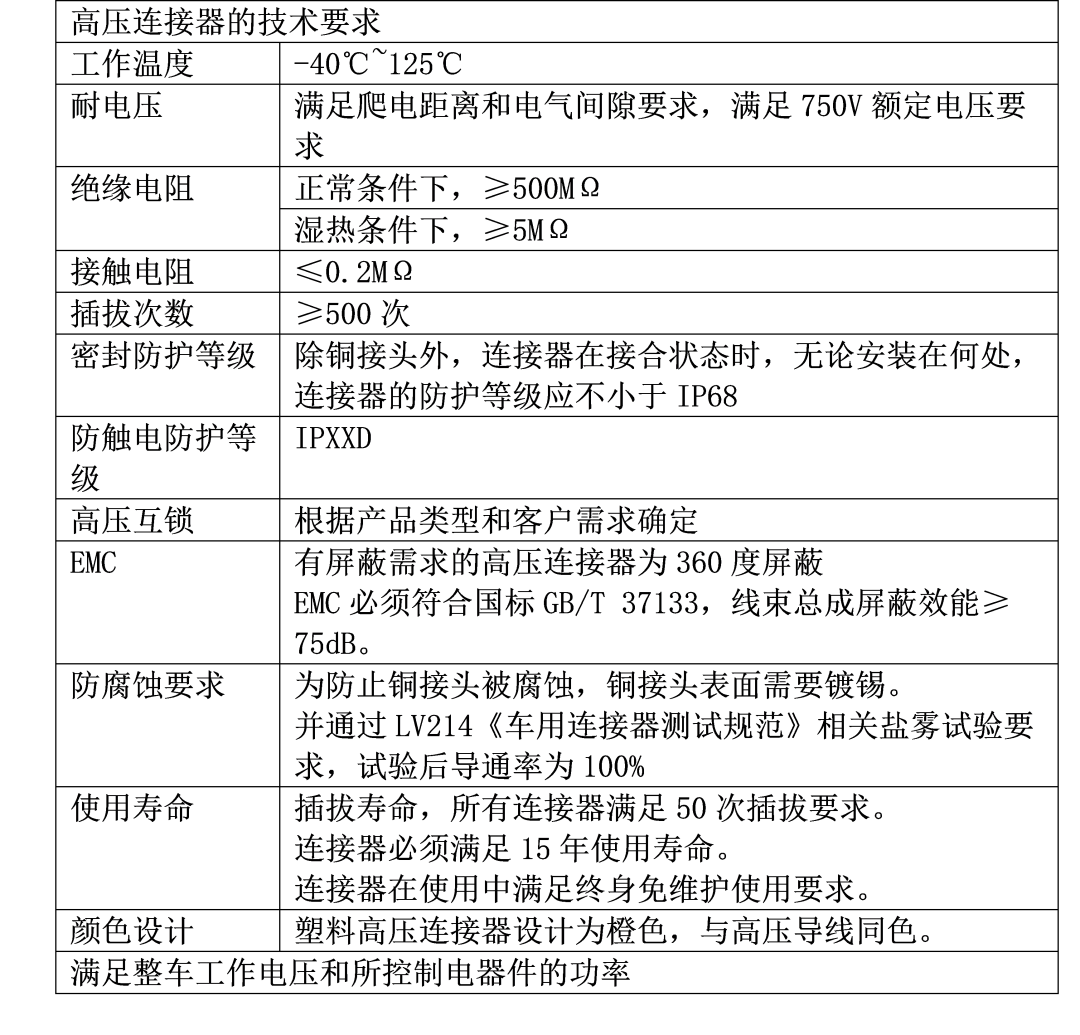

Iimfuno ngokubanzi kwizihlanganisi zombane ophezulu

Iziqhagamshelo zombane ophezulu kufuneka zihambelane neemfuno ezichazwe yi-SAE J1742 kwaye zibe nezi mfuno zobugcisa zilandelayo:

Iimfuno zobugcisa ezichazwe yi-SAE J1742

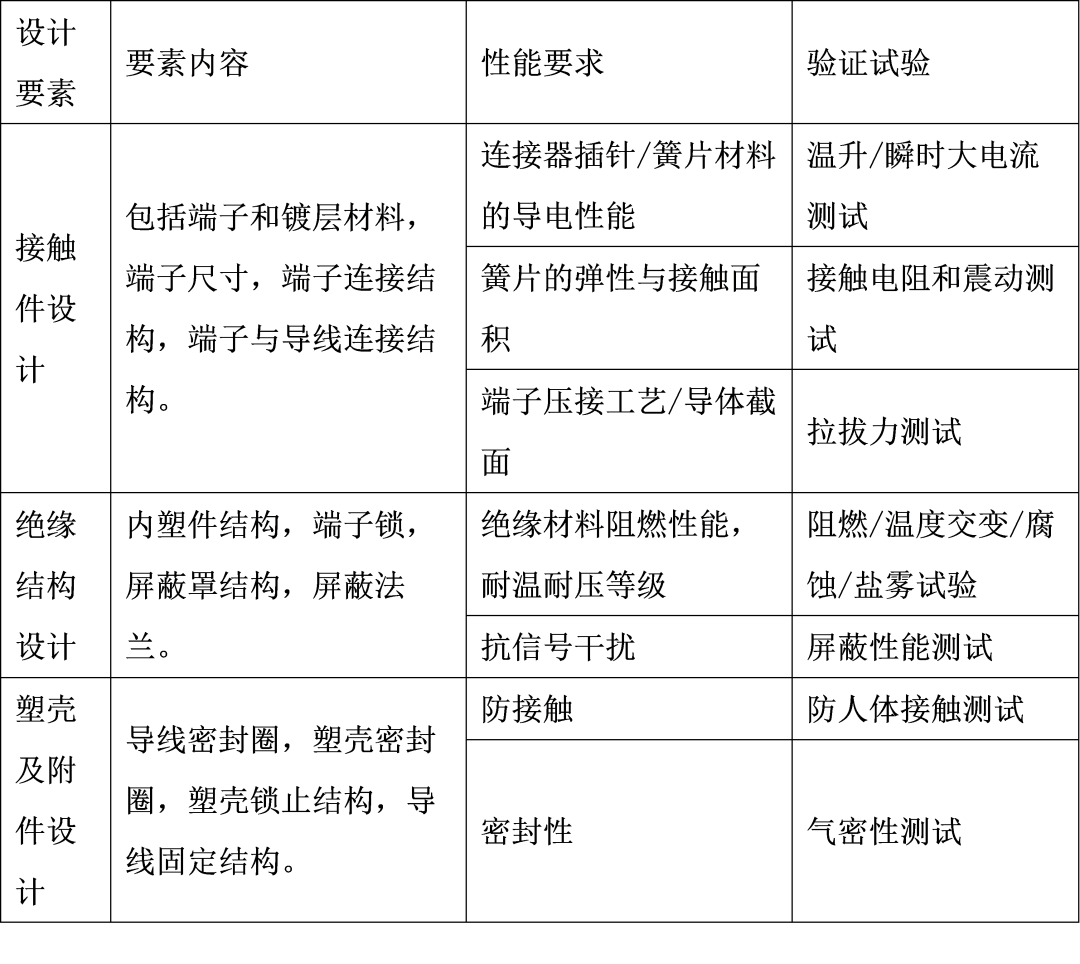

Izinto zokuyila zezihlanganisi zombane ophezulu

Iimfuno ze-high-voltage connectors kwiinkqubo eziphezulu ze-voltage ziquka kodwa azikhawulelwanga: umbane ophezulu kunye nokusebenza okuphezulu kwangoku; isidingo sokukwazi ukufikelela kumanqanaba aphezulu okukhusela phantsi kweemeko ezahlukeneyo zokusebenza (ezifana nokushisa okuphezulu, ukungcangcazela, impembelelo yokungqubana, uthuli kunye nokungangeni kwamanzi, njl.); Yiba nokufakela; ube nokusebenza kakuhle kwe-electromagnetic shielding; ixabiso kufuneka libe liphantsi kangangoko kwaye lomelele.

Ngokwezi mpawu zingentla kunye neemfuno ezinokuthi i-high-voltage connectors kufuneka ibe nayo, ekuqaleni koyilo lwe-high-voltage connectors, ezi zinto zilandelayo zokuyila kufuneka zithathelwe ingqalelo kunye noyilo olujoliswe kuyo kunye nokuqinisekiswa kovavanyo lwenziwa.

Uluhlu lokuthelekisa izinto zokuyila, ukusebenza okuhambelanayo kunye neemvavanyo zokuqinisekisa i-high-voltage connectors

Uhlalutyo lokungaphumeleli kunye nemilinganiselo ehambelanayo ye-high-voltage connectors

Ukuze kuphuculwe ukuthembeka koyilo lokudibanisa, imodi yokungaphumeleli kwayo kufuneka iqale ihlalutywe ukwenzela ukuba umsebenzi ohambelanayo woyilo lokuthintela unokwenziwa.

Izihlanganisi zihlala zineendlela ezintathu eziphambili zokungaphumeleli: ukudibanisa kakubi, ukugquma okungahambi kakuhle, kunye nokulungiswa okukhululekile.

(1) Ngoqhagamshelwano olubi, izibonakaliso ezifana nokuchasana koqhagamshelwano lwe-static, ukuchasana koqhagamshelwano oluguqukayo, amandla okuhlukanisa umngxuma omnye, iindawo zokudibanisa kunye nokumelana nokungcangcazela kwamacandelo angasetyenziselwa ukugweba;

(2) Kwi-insulator engalunganga, ukuchasana kwe-insulator, izinga lokuthotywa kwexesha le-insulator, izibonakaliso zobungakanani be-insulator, oonxibelelwano kunye nezinye iindawo zingabonwa ukuze zigwebe;

(3) Ukuthembeka kohlobo olusisigxina kunye noluvaliweyo, ukunyamezela kwendibano, umzuzu wokunyamezela, ukudibanisa amandla okugcina i-pin, amandla okufaka i-pin, amandla okugcina phantsi kweemeko zokuxinzelela kwendalo kunye nezinye izibonakaliso ze-terminal kunye nekhonkco zinokuvavanywa ukuze zigwebe.

Emva kokuhlalutya iindlela eziphambili zokungaphumeleli kunye neefom zokungaphumeleli kwesiqhagamshelo, la manyathelo alandelayo anokuthathwa ukuphucula ukuthembeka koyilo lokudibanisa:

(1) Khetha isinxibelelanisi esifanelekileyo.

Ukukhethwa kwezixhumi akufanele kuqwalaselwe kuphela uhlobo kunye nenani leesekethe ezidibeneyo, kodwa ziququzelele ukubunjwa kwezixhobo. Ngokomzekelo, iziqhagamshelo zesetyhula azichatshazelwa kangako yimozulu kunye nezinto ezisebenza ngomatshini kuneziqhagamshelo ezixande, zineengubo ezingaphantsi komatshini, kwaye ziqhagamshelwe ngokuthembekileyo kwiziphelo zocingo, ngoko ke izihlanganisi zeesetyhula kufuneka zikhethwe kangangoko kunokwenzeka.

(2) Inani elikhulu labafowunelwa kwikhonkco, lisezantsi ukuthembeka kwenkqubo. Ngoko ke, ukuba indawo kunye nobunzima buvumela, zama ukukhetha ikhonkco kunye nenani elincinci labafowunelwa.

(3) Xa ukhetha ikhonkco, iimeko zokusebenza zezixhobo kufuneka ziqwalaselwe.

Oku kungenxa yokuba umthwalo opheleleyo wangoku kunye nobuninzi bokusebenza okwangoku bekhonkco bahlala bemiselwa ngokusekelwe kubushushu obuvunyelweyo xa usebenza phantsi kweemeko eziphezulu zokushisa kwendawo engqongileyo. Ukuze kuncitshiswe ukushisa okusebenzayo kwesiqhagamshelo, iimeko zokutshatyalaliswa kobushushu zekhonkco kufuneka ziqwalaselwe ngokupheleleyo. Ngokomzekelo, abafowunelwa kude ukusuka kumbindi wekhonkco bangasetyenziselwa ukudibanisa ukunikezelwa kwamandla, okwenza kube lula ukutshabalalisa ubushushu.

(4) Ukungangeni kwamanzi kunye nokuchasana nokubola.

Xa isinxibelelanisi sisebenza kwindawo eneegesi ezitshabalalisayo kunye ne-liquids, ukwenzela ukuba kuthintelwe ukubola, ingqalelo kufuneka ihlawulwe kwithuba lokuyifakela ngokuthe tye ukusuka kwicala ngexesha lokufakela. Xa iimeko zifuna ufakelo oluthe nkqo, ulwelo kufuneka luthintelwe ukuba lungaphumi kwisidibanisi ecaleni kwemikhombandlela. Ngokuqhelekileyo sebenzisa izihlanganisi ezingenamanzi.

Amanqaku aphambili kuyilo loqhagamshelwano lwe-high-voltage connector

Itekhnoloji yoqhagamshelwano loqhagamshelwano ikakhulu iphonononga indawo yoqhagamshelwano kunye namandla oqhagamshelwano, kubandakanywa uqhagamshelwano loqhagamshelwano phakathi kweetheminali kunye neengcingo, kunye noqhagamshelo loqhagamshelwano phakathi kweetheminali.

Ukuthembeka kwabafowunelwa ngumba obalulekileyo ekumiseleni ukuthembeka kwenkqubo kwaye ikwayinxalenye ebalulekileyo yendibano yokubopha iintambo zombane eziphezulu.. Ngenxa yemeko enzima yokusebenza kwezinye iitheminali, iingcingo kunye neziqhagamshelo, uqhagamshelo phakathi kweetheminali kunye neengcingo, kunye noqhagamshelo phakathi kweetheminali kunye neetheminali ziqhelene nokusilela okwahlukeneyo, njengokubola, ukuguga, kunye nokukhululeka ngenxa yokungcangcazela.

Ekubeni ukungaphumeleli kweentambo zombane ezibangelwa ngumonakalo, ukukhululeka, ukuwa, kunye nokungaphumeleli kwe-akhawunti yoqhagamshelwano ngaphezu kwe-50% yokungaphumeleli kuyo yonke inkqubo yombane, ingqwalasela epheleleyo kufuneka ihlawulwe kuyilo lokuthembeka lwabafowunelwa kuyilo lokuthembeka kwenkqubo yombane we-high-voltage yesithuthi.

1. Uqhagamshelwano loqhagamshelwano phakathi kwetheminali kunye nocingo

Uqhagamshelo phakathi kweetheminali kunye neengcingo lubhekisa kuqhagamshelo phakathi kwezi zimbini ngenkqubo yecrimping okanye inkqubo ye-ultrasonic welding. Okwangoku, inkqubo ye-crimping kunye nenkqubo ye-welding ye-ultrasonic isetyenziswa ngokuqhelekileyo kwiintambo ze-high-voltage, nganye ineenzuzo zayo kunye nokungona kwayo.

(1) Inkqubo yeCrimping

Umgaqo-nkqubo wenkqubo ye-crimping kukusebenzisa amandla angaphandle ukucinezela ngokwasemzimbeni ucingo lomqhubi kwindawo ekrunekileyo ye-terminal. Umphakamo, ububanzi, ubume obunqamlezileyo kunye namandla okutsalwa kwe-terminal crimping zezona ziqulatho zingundoqo zomgangatho wokukrazula kwe-terminal, omisela umgangatho wokukrazula.

Nangona kunjalo, kufuneka kuqatshelwe ukuba i-microstructure yayo nayiphi na indawo eqinile ecutshungulwayo ihlala irhabaxa kwaye ingalingani. Emva kokuba ii-terminals kunye neengcingo zinqanyuliwe, akusiyo uqhagamshelwano lwendawo yonke yoqhagamshelwano, kodwa uqhagamshelwano lwamanqaku athile ahlakazekile kwindawo yoqhagamshelwano. , indawo yokudibanisa yokwenene kufuneka ibe yincinci kunomgangatho woqhagamshelwano lwethiyori, okusesona sizathu sokuba ukuchasana koqhagamshelwano lwenkqubo ye-crimping kuphezulu.

I-Mechanical crimping ichaphazeleka kakhulu yinkqubo ye-crimping, njengoxinzelelo, ukuphakama kwe-crimping, njl njl. Ukulawulwa kwemveliso kufuneka kuqhutywe ngeendlela ezifana nokuphakama kwe-crimping kunye nohlalutyo lweprofayili / uhlalutyo lwe-metallographic. Ngoko ke, ukuhambelana kwe-crimping yenkqubo ye-crimping yi-avareji kwaye isixhobo sinxitywe Impembelelo enkulu kwaye ukuthembeka kuphakathi.

Inkqubo ye-crimping ye-crimping yomatshini ikhulile kwaye inoluhlu olubanzi lwezicelo eziphathekayo. Yinkqubo yemveli. Phantse bonke ababoneleli abakhulu banemveliso yocingo olusebenzisa le nkqubo.

Iiprofayili zoqhagamshelwano zeterminal kunye neengcingo usebenzisa inkqubo yecrimping

(2) Inkqubo ye-welding ye-ultrasonic

I-Ultrasonic welding isebenzisa amaza e-vibration e-high-frequency ukuze idlulisele kwindawo yezinto ezimbini eziza kufakwa. Phantsi koxinzelelo, imiphezulu yezinto ezimbini ziyakhuhla enye kwenye ukuze zenze ukudibanisa phakathi kweeleya zemolekyuli.

I-Ultrasonic welding isebenzisa i-ultrasonic generator ukuguqula i-50/60 Hz yangoku ibe yi-15, 20, 30 okanye 40 KHz amandla ombane. Amandla ombane aphezulu aguqulwayo aguqulwa kwakhona abe yintshukumo yomatshini yokuphindaphinda okufanayo nge-transducer, kwaye emva koko ukunyakaza komatshini kudluliselwa kwintloko ye-welding ngokusebenzisa isethi yezixhobo zophondo ezinokutshintsha i-amplitude. Intloko ye-welding idlulisela amandla okungcangcazela afunyenweyo kumdibaniso we-workpiece ukuba idityaniswe. Kulo mmandla, amandla okungcangcazela aguqulwa abe ngamandla obushushu ngokusebenzisa ukukhuhlana, ukunyibilika kwesinyithi.

Ngokumalunga nokusebenza, inkqubo ye-welding ye-ultrasonic inokuchasana okuncinci kunye nokufudumala okuphantsi kwe-overcurrent ixesha elide; ngokwemiqathango yokhuseleko, inokwethenjelwa kwaye akulula ukuyikhulula kunye nokuwa phantsi kokungcangcazela kwexesha elide; ingasetyenziselwa ukuwelda phakathi kwezinto ezahlukeneyo; ichatshazelwa yi-oxidation yomhlaba okanye ukugquma Okulandelayo; umgangatho we-welding unokugwetywa ngokubeka iliso kwiifom zamaza ezifanelekileyo zenkqubo ye-crimping.

Nangona iindleko zezixhobo zenkqubo ye-welding ye-ultrasonic iphezulu kakhulu, kwaye iinxalenye zetsimbi ezinokuthi zifakwe kwi-welded azikwazi ukuba zikhulu kakhulu (ngokubanzi ≤5mm), i-ultrasonic welding yinkqubo yomatshini kwaye akukho ukuhamba kwangoku ngexesha lenkqubo ye-welding yonke, ngoko ke akukho Imiba yokuqhuba ukushisa kunye nokumelana nokuxhatshazwa yimizila ezayo ye-high-voltage wire harness welding.

Iiterminals kunye nabaqhubi abane-welding ye-ultrasonic kunye namacandelo abo oqhagamshelwano

Kungakhathaliseki ukuba inkqubo ye-crimping okanye inkqubo ye-welding ye-ultrasonic, emva kokuba i-terminal ixhunyiwe kwi-wire, amandla ayo okukhupha kufuneka ahlangabezane neemfuno eziqhelekileyo. Emva kokuba ucingo luqhagamshelwe kwisidibanisi, amandla okutsalwa akufanele abe ngaphantsi kobuncinci bokutsala amandla.

Ixesha lokuposa: Dec-06-2023