1.0

Ubungakanani besicelo kunye nengcaciso

1.1 Ifanele i-automotive wiring harness kabini-udonga ubushushu shrinkable iimveliso series tube.

1.2 Xa isetyenziswa kwiintambo zocingo zemoto, kwi-terminal wiring, iingcingo zocingo kunye ne-wireless end wiring, iinkcukacha kunye nemilinganiselo yetyhubhu eshwabeneyo yobushushu ihambelana nereferensi yobungakanani obuncinci kunye nobukhulu bemilinganiselo yendawo egqunyiweyo.

2.0

Ukusetyenziswa kunye nokukhetha

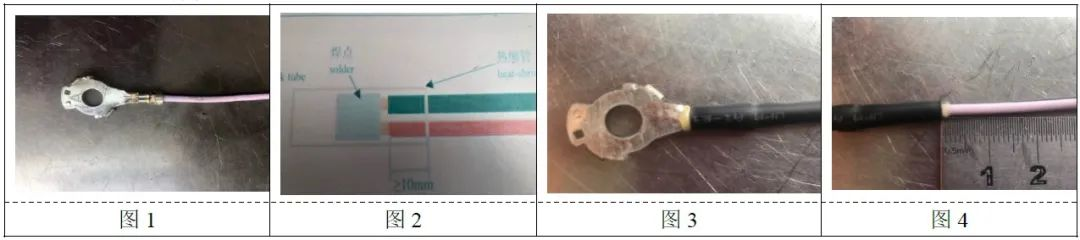

2.1 Idayagram ye-terminal wiring

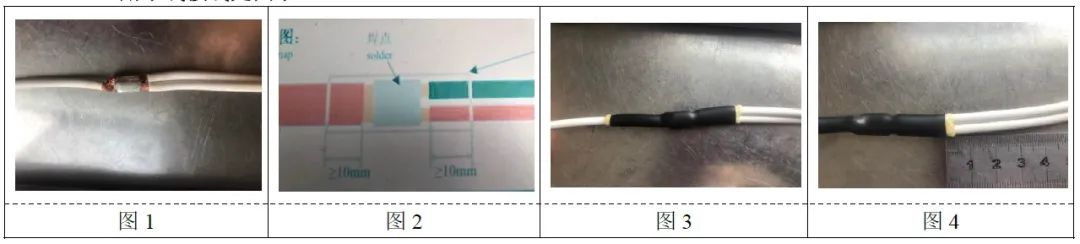

2.2 Idayagram yoqhagamshelwano lweengcingo

2.3 Imiyalelo yokusetyenziswa nokukhetha

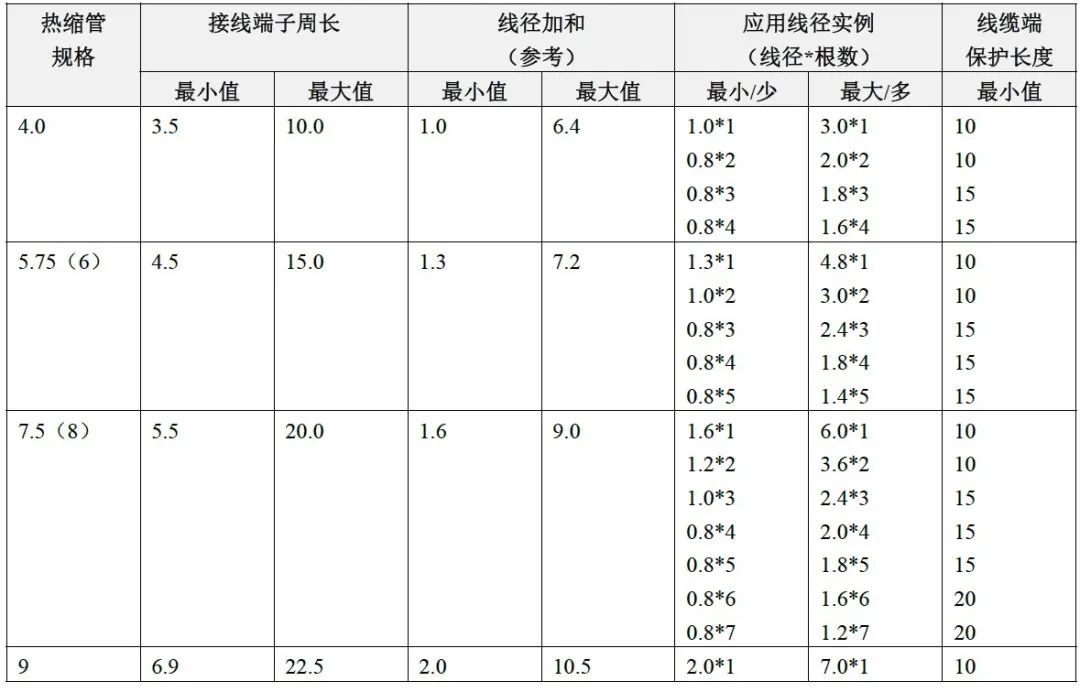

2.3.1Ngokoluhlu oluncinci kunye nobuninzi be-circumference yecandelo eligubungelelweyo le-terminal (emva kwe-crimping), ubuncinane kunye noluhlu oluphezulu olusebenzayo lwe-diameter ye-cable kunye nenani leentambo, khetha ubungakanani obufanelekileyo betyhubhu yokunciphisa ukushisa, jonga ngezantsi ngeenkcukacha zeThebhile 1.

2.3.2Qaphela ukuba ngenxa yeemeko ezahlukeneyo zokusetyenziswa kunye neendlela, unxulumano olucetyiswayo lwembalelwano kunye noluhlu olukwiThebhile 1 lwenzelwe ireferensi kuphela; kuyimfuneko ukumisela imbalelwano efanelekileyo esekelwe kusetyenziso olululo kunye nokuqinisekiswa, kwaye wenze uqokelelo lwedathabheyisi.

2.3.3Kubudlelwane obuhambelanayo kwiThebhile 1, "Umzekelo we-Application Wire Diameter" unika ubuncinci okanye ubuninzi bedayamitha yocingo enokuthi isetyenziswe xa kukho iingcingo ezininzi zocingo olufanayo. Nangona kunjalo, kwisicelo sokwenene, kukho iingcingo ezininzi ezineedamitha ezahlukeneyo zocingo kwelinye icala loqhagamshelwano lwentambo. Ngeli xesha, unokuthelekisa i-"sum of wire diameters" ikholamu kwiThebhile 1. Isixa sangempela se-diameters yocingo kufuneka sibe phakathi koluhlu lwee-dimeters ze-wire, kwaye emva koko uqinisekise ukuba luyasebenza.

2.3.4Kwi-terminal i-wiring okanye i-wiring ye-wire, i-circumference esebenzayo okanye uluhlu lwe-wire diameter ye-tube ehambelanayo yokushisa ukushisa kufuneka ithathelwe ingqalelo, kwaye kufuneka ikwazi ukugubungela ngaxeshanye ubuncinci kunye nemilinganiselo ephezulu (i-circumference okanye i-diameter ye-wire) yento egqunyiweyo. Kungenjalo, kufuneka kunikwe ingqwalaselo ephambili ekuzameni ukusebenzisa iityhubhu ezishwabeneyo zobushushu zezinye iinkcukacha ukuze kubonwe ukuba ziyakwazi ukuhlangabezana neemfuno zokusetyenziswa; okwesibini, uyila kwaye utshintshe indlela yocingo ukuze ikwazi ukuhlangabezana neemfuno ngexesha elinye; okwesithathu, yongeza ifilimu okanye i-rubber particles kwisiphelo esingenako ukuhlangabezana nexabiso eliphezulu, ubuncinci Yongeza ishubhu yokunciphisa ukushisa ukuya kwelinye icala; okokugqibela, yenza ngokwezifiso imveliso yetyhubhu eshwabeneyo yobushushu okanye esinye isisombululo sokutywina sokuvuza kwamanzi.

2.3.5Ubude bombhobho otshisayo obushushu kufuneka bumiselwe ngokuhambelana nobude bokwenene bokukhusela isicelo. Ngokuxhomekeke kububanzi bocingo, ityhubhu yokucutha ubushushu edla ngokusetyenziswa kwi-terminal wiring yi-25mm ~ 50mm ubude, kwaye ityhubhu eshwabeneyo yobushushu esetyenziselwa ukubiyela ucingo yi-40 ~ 70mm ubude. Kunconywa ukuba ubude betyhubhu yokukhusela i-shubhu yokukhusela i-cable insulation yi-10mm ~ 30mm, kwaye ikhethwe ngokweenkcukacha ezahlukeneyo kunye nobukhulu. Jonga iTheyibhile 1 ngezantsi ngeenkcukacha. Okukhona ubude bokhuseleko, kokukhona isiphumo sokutywinwa singangeni manzi singcono.

2.3.6Ngokuqhelekileyo, ngaphambi kokukrazula ii-terminals okanye ukukrazula / ukudibanisa iingcingo, faka ityhubhu yokunciphisa ukushisa kwiintambo kuqala, ngaphandle kwendlela yokucima i-wiring yokuphela kwamanzi (oko kukuthi, zonke iingcingo ziphela ekupheleni, kwaye akukho ndawo okanye i-terminal kwelinye icala) I-Wiring). Emva kwe-crimping, sebenzisa umatshini wokunciphisa ukushisa, umpu womoya oshushu, okanye enye indlela yokufudumeza ethile ukwenza ukutshisa ukutshisa ukucutha ityhubhu yokunciphisa ukushisa kwaye uyilungise kwindawo yokukhusela eyilelwe.

2.3.7Emva kokunciphisa ukushisa, ngokweemfuno zoyilo okanye zokusebenza, ukuhlolwa okubonakalayo kukhethwa ukuqinisekisa ukuba umgangatho womsebenzi ulungile. Umzekelo, khangela inkangeleko iyonke kwizinto ezingaqhelekanga ezifana ne-bulges, inkangeleko engalinganiyo (mhlawumbi kungabikho ukushisa), ukukhuselwa kwe-asymmetric (indawo ishukumile), umonakalo ophezulu, njl. khangela iziphelo zombini Ingaba isigqubuthelo siqinile, nokuba iglue iyaphuphuma kwaye ukutywinwa ekupheleni kocingo kulungile (ngokuqhelekileyo ukuphuphuma kwe-2 ~ 5mm); ingaba ukukhuselwa kokutywinwa kwi-terminal kulungile, nokuba i-glue igqithise ngaphezu komda ofunekayo ngokuyila, ngaphandle koko inokuchaphazela indibano. njl.

2.3.8Xa kuyimfuneko okanye kuyimfuneko, iisampulu iyafuneka ukuze kuhlolwe isitywina esingenamanzi (isixhobo sokuhlola esikhethekileyo).

2.3.9Isikhumbuzo esikhethekileyo: Iitheminali zentsimbi ziqhuba ubushushu ngokukhawuleza xa zishushu. Xa kuthelekiswa neengcingo ezigqunyiweyo, zifunxa ubushushu obuninzi (iimeko ezifanayo kunye nexesha elifanayo zifunxa ubushushu obuninzi), ziqhube ubushushu ngokukhawuleza (ukulahleka kobushushu), kwaye zisebenzise ubushushu obuninzi ngexesha lokufudumeza kunye nokusebenza kokuncipha. Ubushushu bukhulu ngokwethiyori.

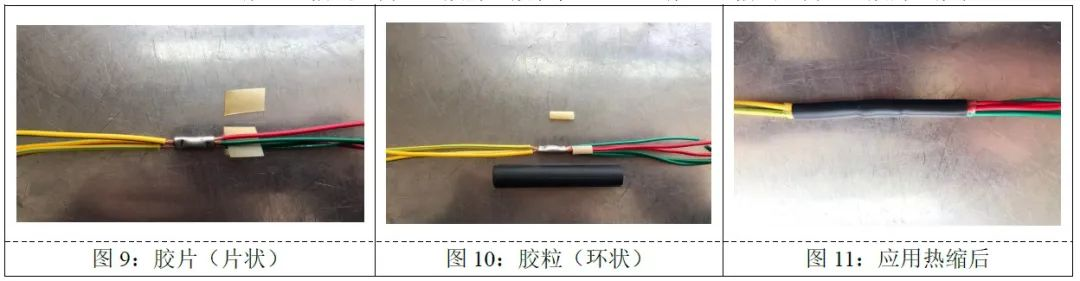

2.3.10Ukusetyenziswa kunye needayamitha ezinkulu zocingo okanye inani elikhulu leentambo, xa i-adhesive eshushu iyancibilika ye-tube yokunciphisa ukushisa ngokwayo ayanele ukuzalisa izikhewu phakathi kweentambo, kucetyiswa ukuba kufakwe amaqhekeza e-rubber (i-ring-shaped) okanye ifilimu (i-sheet-shaped) Ukwandisa inani leglue phakathi kweengcingo ukuze kuqinisekiswe umphumo wokutywinwa kwamanzi. Kunconywa ukuba ubungakanani bombhobho wokunciphisa ukushisa ngu-≥14, ububanzi bocingo bukhulu kwaye inani leentambo likhulu (≥2), njengoko kuboniswe kwiMifanekiso 9, 10, kunye ne-11. Ngokomzekelo, i-18.3 inkcazo yokushisa ukushisa ityhubhu, i-8.0mm ye-wire diameter, i-2 iingcingo, idinga ukongeza ifilimu okanye i-rubber ye-particle; I-5.0mm yocingo ububanzi, iingcingo ezi-3, kufuneka zongeze ifilimu okanye amaqhekeza erabha.

2.4 Itheyibhile yoKhetho yetheminali kunye neesayizi zedayamitha yocingo ezihambelana neenkcukacha zetyhubhu yokuncipha kobushushu (iyunithi: mm)

3.0

Ukuncipha kobushushu kunye nomatshini wokucutha ubushushu kwityhubhu yokucutha ubushushu kwiintambo zokubopha iintambo zemoto

3.1 Uhlobo lweCrawler lusebenza ngokuqhubekayo umatshini wokucutha ubushushu

Eziqhelekileyo ziquka TE (Tyco Electronics)'s M16B, M17, kunye M19 series ubushushu oomatshini shwabanisa, Shanghai Rugang Automation kaThixo TH801, TH802 uthotho oomatshini ukushwabana ubushushu, kunye noomatshini ukushwabana ubushushu Henan Tianhai, njengoko kubonisiwe kwiFigure 12 kunye 13.

3.2 Umatshini wokucutha ubushushu ngokufakwa

Eziqhelekileyo ziquka i-TE (iTyco Electronics) ye-RBK-ILS Processor MKIII yokunciphisa ubushushu umatshini, i-Shanghai Rugang Automation's TH8001-plus digital networked networked terminal wire heat shrink machine, TH80-OLE series online machine shrinking machine, etc., njengoko kubonisiwe kuMfanekiso 14, 15 no-16 kubonisiwe.

3.3 Imiyalelo yemisebenzi yokunciphisa ubushushu

3.3.1Ezi ntlobo zingentla zoomatshini bokucutha ubushushu zizo zonke izixhobo zokuthoba ubushushu ezikhupha ubushushu obuthile kwindibano yokusebenzela ukuba bubushushu. Emva kokuba ityhubhu yokunciphisa ubushushu kwindibano ifikelele ekunyukeni okwaneleyo kobushushu, ityhubhu yokuncipha kobushushu iyancipha kwaye i-adhesive inyibilika eshushu iyanyibilika. Idlala indima yokubopha ngokuqinileyo, ukutywina kunye nokukhulula amanzi.

3.3.2Ukuchaneka ngakumbi, inkqubo yokuncipha kobushushu ngokwenene yityhubhu yokuncipha kobushushu kwindibano. Ngaphantsi kweemeko zokufudumeza kumatshini wokunciphisa ubushushu, ityhubhu yokucutha ubushushu ifikelela kwiqondo lobushushu lokuncipha kobushushu, ityhubhu yokuncipha kobushushu iyancipha, kwaye incamathela eshushu enyibilikayo ifikelela kwiqondo lobushushu lokunyibilika. , i-glue eshushu iyancibilika igeleza ukuzalisa izikhewu kwaye ibambelele kwi-workpiece egqunyiweyo, ngaloo ndlela yenza isitywina somgangatho ongenamanzi okanye icandelo lendibano yokukhusela ekhuselayo.

3.3.3Iintlobo ezahlukeneyo zoomatshini bokucutha ubushushu bunamandla ahlukeneyo okufudumeza, oko kukuthi, ubungakanani bobushushu obuphuma kwindibano yokusebenza ngexesha leyunithi, okanye ukusebenza kakuhle kobushushu, kuyahluka. Ezinye zikhawuleza, ezinye zicotha, ixesha lokusebenza lokunciphisa ubushushu liya kwahluka (umatshini wokukhasa ulungelelanisa ixesha lokufudumeza ngesantya), kunye nobushushu besixhobo ekufuneka sisetwe buya kwahluka.

3.3.4Nokuba oomatshini bokunciphisa ubushushu bemodeli efanayo baya kuba nempumelelo eyahlukileyo yokukhupha ubushushu ngenxa yokungafani kwexabiso lemveliso yokufudumeza isixhobo, iminyaka yezixhobo, njl.

3.3.5Amaqondo obushushu abekiweyo aba matshini bangentla bokunciphisa ubushushu aphakathi kwe-500 ° C kunye ne-600 ° C, kunye nexesha elifanelekileyo lokufudumeza (umatshini wokukhasa ulungelelanisa ixesha lokufudumeza ngesantya) ukwenza imisebenzi yokunciphisa ubushushu.

3.3.6Nangona kunjalo, iqondo lokushisa elibekiweyo lesixhobo sokunciphisa ubushushu alibonisi ubushushu bokwenyani obufikelelwe yindibano yokuncipha kobushushu emva kokuba ishushu. Ngamanye amazwi, ityhubhu yokunciphisa ubushushu kunye nezixhobo zayo zokusebenza azidingi ukufikelela kwiidigri ezingamakhulu aliqela abekwe ngumatshini wokucutha ubushushu. Ngokuqhelekileyo, kufuneka zifikelele kwiqondo lobushushu le-90 ° C ukuya kwi-150 ° C ngaphambi kokuba zibe nobushushu kwaye zisebenze njengetywina lokukhupha amanzi.

3.3.7Iimeko ezifanelekileyo zenkqubo kufuneka zikhethwe kwimisebenzi yokunciphisa ubushushu ngokusekelwe kubukhulu betyhubhu yokunciphisa ubushushu, ukuqina kunye nokuthamba kwezinto eziphathekayo, umthamo kunye neempawu zokufunxa ubushushu bento egqunyiweyo, umthamo kunye neempawu zokufunxa ubushushu besixhobo sokwenza izixhobo, kunye nobushushu obuphantsi.

3.3.8Unokusebenzisa i-thermometer kwaye uyibeke kumngxuma okanye itonela yesixhobo sokunciphisa ubushushu phantsi kweemeko zenkqubo, kwaye ujonge ubushushu obuphezulu obufikelelwa yithemomitha ngexesha lokwenyani njengokulinganisa amandla okuvelisa ubushushu besixhobo sokunciphisa ubushushu ngelo xesha. (Qaphela ukuba phantsi kweemeko ezifanayo zenkqubo yokunciphisa ubushushu, ukunyuka kwamaqondo obushushu kwithemometha kuya kwahluka ekuphakameni kweqondo lokushisa kwi-workpiece ye-heat shrink ngenxa yomahluko wevolumu kunye nokunyuka kwamaqondo obushushu emva kokufudumeza, ngoko ukunyuka kobushushu kwethemometha Ukunyuka kobushushu obulinganisiweyo kusetyenziswa kuphela njengereferensi yokulinganisa iimeko zenkqubo kwaye ayimeli ukunyuka kwamaqondo okushisa apho indibano yokufudumala iya kufikelela)

3.3.9Imifanekiso ye-thermometer iboniswe kwiMifanekiso 18 kunye ne-19. Ngokuqhelekileyo, iprobe ethile yokushisa iyadingeka.

Ixesha lokuposa: Nov-14-2023