Njengoko abaqhubi be-aluminiyam besanda kusetyenziswa kwiintambo zeentambo zeemoto, eli nqaku lihlalutya kwaye lilungelelanise iteknoloji yoqhagamshelwano lwe-aluminium yokudibanisa amandla ombane, kwaye ihlalutya kwaye ithelekisa ukusebenza kweendlela ezahlukeneyo zokudibanisa ukuququzelela ukhetho lwamva lweendlela zokudibanisa iintambo zombane ze-aluminium.

01 Isishwankathelo

Ngokukhuthazwa kokusetyenziswa kwabaqhubi be-aluminium kwiintambo zeentambo zemoto, ukusetyenziswa kwee-aluminium conductors endaweni yabaqhubi bezobhedu bendabuko kuyanda ngokuthe ngcembe. Nangona kunjalo, kwinkqubo yokusetyenziswa kweengcingo ze-aluminium ezithatha indawo yeengcingo zobhedu, i-electrochemical corrosion, ukushisa okuphezulu, kunye ne-conductor oxidation ziingxaki ekufuneka zijamelane nazo kwaye zisonjululwe ngexesha lesicelo. Ngexesha elifanayo, ukusetyenziswa kweengcingo ze-aluminium ezithatha indawo yeengcingo zobhedu kufuneka zihlangabezane neemfuno zeengcingo zokuqala zobhedu. Iimpawu zombane kunye nezomatshini ukuphepha ukuthotywa kokusebenza.

Ukuze kulungiswe iingxaki ezifana ne-electrochemical corrosion, ubushushu obuphezulu be-creep, kunye ne-conductor oxidation ngexesha lokusetyenziswa kweengcingo ze-aluminium, okwangoku kukho iindlela ezine zokudibanisa eziqhelekileyo kwishishini, ezizezi: i-friction welding kunye ne-pressure welding, i-friction welding, i-ultrasonic welding, kunye ne-plasma welding.

Oku kulandelayo luhlalutyo kunye nothelekiso lwentsebenzo yemigaqo yoqhagamshelo kunye nezakhiwo zezi ntlobo zine zoqhagamshelo.

02 I-welding ye-friction kunye ne-welding yoxinzelelo

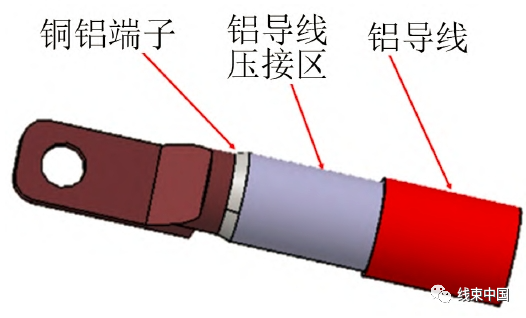

I-Friction welding kunye noxinzelelo lokudibanisa, sebenzisa kuqala iintonga zobhedu kunye ne-aluminiyam yokudibanisa i-friction welding, kwaye emva koko ugxininise iintonga zobhedu ukwenza uqhagamshelo lombane. Iintonga ze-aluminiyam zenziwe ngoomatshini kwaye zenziwe ukuba zenze i-aluminium crimp ends, kunye ne-copper kunye ne-aluminiyam terminals ziveliswa. Emva koko ucingo lwe-aluminiyam lufakwe kwisiphelo se-aluminiyam ye-aluminiyam ye-terminal yobhedu-aluminiyam kunye ne-hydraulically crimped ngokusebenzisa izixhobo ze-wire harness crimping zendabuko ukugqiba ukudibanisa phakathi komqhubi we-aluminium kunye ne-terminal yobhedu-aluminium, njengoko kubonisiwe kuMfanekiso 1.

Xa kuthelekiswa nezinye iifom zokudibanisa, i-friction welding kunye ne-pressure welding yenza indawo yokutshintsha i-copper-aluminium alloy transition ngokusebenzisa i-friction welding yeentonga zobhedu kunye neentonga ze-aluminium. Umphezulu we-welding ufana kakhulu kwaye uxinene, ukuthintela ngokufanelekileyo ingxaki yokunyuka kwe-thermal ebangelwa yi-coefficients yokwandiswa kwe-thermal eyahlukeneyo yobhedu kunye ne-aluminium. , Ukongezelela, ukubunjwa kwendawo yenguqu ye-alloy kwakhona kuthintela ngokufanelekileyo ukubola kwe-electrochemical okubangelwa yimisebenzi eyahlukeneyo yetsimbi phakathi kobhedu kunye ne-aluminium. Ukutywinwa okulandelayo kunye neetyhubhu zokucutha ubushushu kusetyenziswa ukwahlula isitshizi setyuwa kunye nomphunga wamanzi, okuthintela ngokufanelekileyo ukwenzeka kwe-electrochemical corrosion. Ngokusebenzisa i-hydraulic crimping yocingo lwe-aluminium kunye ne-aluminium crimp ekupheleni kwe-terminal yethusi-aluminium, isakhiwo se-monofilament somqhubi we-aluminium kunye noluhlu lwe-oxide eludongeni lwangaphakathi lwe-aluminium crimp end luyatshatyalaliswa kwaye luhlanjululwe, kwaye ke ukubanda kugqitywe phakathi kweengcingo zodwa kunye naphakathi kwe-aluminium endor conductor kunye nodonga lwe-icrimp conductor. Umdibaniso we-welding uphucula ukusebenza kombane woxhulumaniso kwaye unikezela ngowona matshini unokuthenjwa.

03 Ukuwelda kwefriction

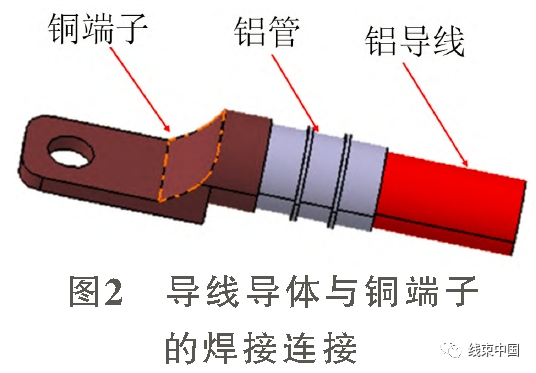

I-friction welding isebenzisa ityhubhu ye-aluminiyam ukukrazula kunye nokubumba umqhubi we-aluminium. Emva kokunqumla ubuso bokuphela, i-welding ye-friction yenziwa nge-terminal yobhedu. Uxhulumaniso lwe-welding phakathi komqhubi wocingo kunye ne-terminal yobhedu lugqitywe nge-welding ye-friction, njengoko kuboniswe kwi-Figure 2.

I-friction welding idibanisa iingcingo ze-aluminiyam. Okokuqala, ityhubhu ye-aluminium ifakwe kwi-conductor yocingo lwe-aluminium ngokusebenzisa i-crimping. Ulwakhiwo lwe-monofilament lomqhubi lufakwe iplastiki ngokusebenzisa i-crimping ukwenza i-cross circular cross-section. Emva koko i-welding cross-section iyancipha ngokujika ukugqiba inkqubo. Ukulungiswa kweendawo ze-welding. Esinye isiphelo se-terminal yobhedu sisakhiwo soxhumo lombane, kwaye esinye isiphelo yindawo yokudibanisa i-welding ye-terminal yobhedu. Umphezulu wodibaniso welding yetheminali yobhedu kunye nomphezulu we-welding yocingo lwe-aluminiyam zidityaniswe kwaye ziqhagamshelwe nge-welding ye-friction, kwaye ke i-flash ye-welding inqunyulwe kwaye imile ukugqiba inkqubo yokudibanisa i-welding wire aluminium.

Xa kuthelekiswa nezinye iifom zokudibanisa, i-friction welding yenza uxhumano lwenguqu phakathi kobhedu kunye ne-aluminium ngokusebenzisa i-friction welding phakathi kwee-terminals zethusi kunye neengcingo ze-aluminium, ngokufanelekileyo ukunciphisa i-electrochemical corrosion yobhedu kunye ne-aluminium. Indawo yokutshintsha i-copper-aluminiyam ye-welding ivalwe nge-adhesive heat shrink tubing kwisigaba samva. Indawo ye-welding ayiyi kubonakaliswa emoyeni kunye nomswakama, iyancipha ngakumbi i-corrosion. Ukongezelela, indawo yokuthungatha apho umqhubi we-aluminium udibaniswa ngokuthe ngqo kwi-terminal yobhedu ngokusebenzisa i-welding, eyandisa ngokufanelekileyo ukukhupha amandla okudibanisa kunye nokwenza inkqubo yokucubungula ilula.

Nangona kunjalo, izinto ezingeloncedo zikwakhona kuqhagamshelo phakathi kweengcingo ze-aluminiyam kunye neetheminali zobhedu-aluminiyam kwi-Figure 1. Ukusetyenziswa kwe-friction welding kubavelisi be-wire harness kufuna izixhobo ezikhethekileyo zokudibanisa i-friction, ene-versatility embi kunye nokwandisa utyalo-mali kwii-asethi ezisisigxina zabakhiqizi be-wire harness. Okwesibini, kwi-welding ye-friction Ngexesha lenkqubo, i-monofilament structure ye-wire i-friction ngokuthe ngqo i-welded kunye ne-terminal yobhedu, okubangelwa i-cavities kwindawo yokudibanisa i-friction welding. Ubukho bothuli kunye nezinye izinto ezingcolileyo buya kuchaphazela umgangatho wokugqibela we-welding, obangela ukungazinzi kwiipropati zomatshini kunye nombane woxhumo lwe-welding.

04 Ultrasonic welding

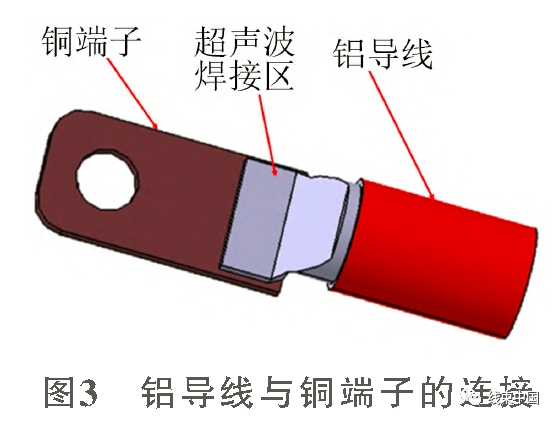

I-Ultrasonic welding yeengcingo ze-aluminium isebenzisa izixhobo ze-welding ze-ultrasonic ukudibanisa iingcingo ze-aluminium kunye neetheminali zethusi. Ngokusebenzisa i-high-frequency oscillation yentloko ye-welding yezixhobo ze-welding ze-ultrasonic, i-aluminium wire monofilaments kunye neengcingo ze-aluminium kunye ne-terminals zethusi zixhunywe kunye ukugqiba ucingo lwe-aluminium kunye nokudityaniswa kwee-terminals zethusi kuboniswe kwi-Figure 3.

Uqhagamshelo lwe-welding ye-Ultrasonic kuxa iingcingo ze-aluminiyam kunye neetheminali zethusi zingcangcazela kumaza e-high-frequency ultrasonic. Ukungcangcazela kunye nokukhuhlana phakathi kobhedu kunye ne-aluminiyam kugqiba unxibelelwano phakathi kobhedu kunye ne-aluminiyam. Ngenxa yokuba zombini ubhedu kunye ne-aluminium ine-face-centered cubic metal crystal structure, kwi-high-frequency oscillation environment Ngaphantsi kwalo mqathango, ukutshintshwa kwe-athomu kwisakhiwo se-crystal metal kugqitywe ukwenza i-alloy transition layer, ukuphepha ngokufanelekileyo ukwenzeka kwe-electrochemical corrosion. Ngexesha elifanayo, ngexesha lenkqubo ye-ultrasonic welding, i-oxide layer phezu kwendawo yomqhubi we-aluminium i-monofilament ihlanjululwe, kwaye emva koko uxhulumaniso lwe-welding phakathi kwe-monofilaments lugqityiwe, oluphucula iimpawu zombane kunye nomatshini wokudibanisa.

Xa kuthelekiswa nezinye iifom zokudibanisa, izixhobo ze-ultrasonic welding sisixhobo esisetyenziswa ngokuqhelekileyo kubenzi beentambo zocingo. Ayifuni mali entsha esisigxina. Ngexesha elifanayo, ii-terminals zisebenzisa i-copper stamped terminals, kwaye i-terminal cost iphantsi, ngoko ineyona nto ingcono kakhulu yeendleko. Nangona kunjalo, kukwakho izinto ezingeloncedo. Xa kuthelekiswa nezinye iifom zoqhagamshelo, i-ultrasonic welding inezakhiwo ezibuthathaka zoomatshini kunye nokunganyangeki kakuhle kokungcangcazela. Ngoko ke, ukusetyenziswa koqhagamshelwano lwe-welding ye-ultrasonic ayikhuthazwa kwiindawo zokungcangcazela eziphezulu.

05 ukuwelda ngePlasma

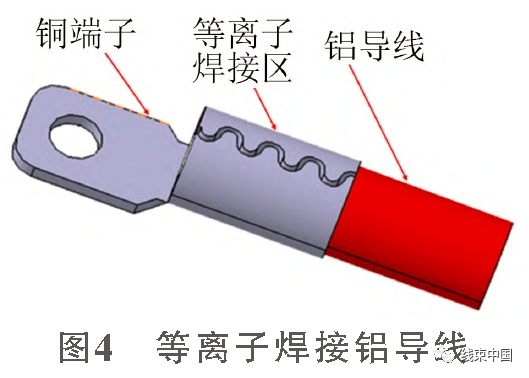

I-Plasma welding isebenzisa i-terminals zethusi kunye neengcingo ze-aluminium zokudibanisa i-crimp, kwaye ngoko ngokufaka i-solder, i-arc ye-plasma isetyenziselwa ukukhupha kunye nokutshisa indawo edibeneyo, inyibilikise i-solder, igcwalise indawo yokudibanisa, kwaye uzalise uxhulumaniso lwe-aluminium yocingo, njengoko kuboniswe kuMfanekiso 4.

I-Plasma welding ye-aluminium conductors kuqala isebenzisa i-plasma welding yeetheminali zobhedu, kwaye ukukrazula kunye nokuqiniswa kwee-aluminium conductors kugqitywa ngokukrazula. I-plasma ye-welding terminals yenze i-barrel-shaped structure emva kokuba i-crimping, kwaye ke indawo ye-welding ye-terminal izaliswe nge-solder ene-zinc, kwaye isiphelo se-crimped yi-Ongeza i-zinc-containing solder. Ngaphantsi kwe-irradiation ye-plasma arc, i-solder ene-zinc ishushu kwaye iyancibilika, kwaye ingena kwi-gap yocingo kwindawo ye-crimping ngokusebenzisa i-capillary action ukugqiba inkqubo yokudibanisa i-terminals zethusi kunye neengcingo ze-aluminium.

Iingcingo ze-aluminium welding ye-Plasma zigqibezela uxhulumaniso olukhawulezayo phakathi kweengcingo ze-aluminiyam kunye neetheminali zobhedu ngokusebenzisa i-crimping, ukubonelela ngeempawu ezithembekileyo zoomatshini. Ngelo xesha, ngexesha lenkqubo ye-crimping, ngomlinganiselo wokunyanzeliswa kwe-70% ukuya kwi-80%, ukutshatyalaliswa kunye nokuxothwa kwe-oxide ye-conductor kugqityiwe, ngokufanelekileyo Ukuphucula ukusebenza kombane, ukunciphisa ukuxhathisa ukudibanisa kwamanqaku okudibanisa, kunye nokuthintela ukufudumeza kwamanqaku okudibanisa. Emva koko yongeza i-solder ene-zinc ekupheleni kwendawo yokuqhawula, kwaye usebenzise i-plasma beam ukuze udibanise kwaye ushushu indawo ye-welding. I-solder ene-zinc iyatshisa kwaye iyancibilika, kwaye i-solder igcwalisa isithuba kwindawo ye-crimping ngokusebenzisa isenzo se-capillary, ukufezekisa amanzi okutshiza ityuwa kwindawo ye-crimping. Ukwahlulwa komphunga kunqanda ukwenzeka kwe-electrochemical corrosion. Kwangaxeshanye, ngenxa yokuba i-solder yodwa kwaye i-buffered, indawo yenguqu iyenziwa, ethintela ngokufanelekileyo ukwenzeka kwe-thermal creep kunye nokunciphisa umngcipheko wokonyuka kokuxhathisa uxhulumaniso phantsi kwezothuso ezishushu nezibandayo. Ngokusebenzisa i-plasma ye-welding yendawo yokudibanisa, ukusebenza kombane kwendawo yokudibanisa kuphuculwe ngokufanelekileyo, kwaye iimpawu zomatshini wendawo yokudibanisa nazo ziphuculwe ngakumbi.

Xa kuthelekiswa nezinye iifom zokudibanisa, i-plasma welding ihlukanisa i-terminals zethusi kunye nabaqhubi be-aluminium ngokusebenzisa inguqu ye-welding layer kunye ne-welding layer eqinisiweyo, ngokufanelekileyo ukunciphisa i-electrochemical corrosion yobhedu kunye ne-aluminium. Kwaye umaleko we-welding oqinisiweyo ugubungela ubuso bokuphela komqhubi we-aluminium ukwenzela ukuba i-terminals zethusi kunye ne-conductor core zingadibani nomoya kunye nomswakama, ngakumbi ukunciphisa i-corrosion. Ukongezelela, inguqu ye-welding layer kunye ne-welding layer eqinisiweyo ilungisa ngokuqinileyo i-terminals zethusi kunye ne-aluminium joints wire joints, ngokufanelekileyo ukwandisa amandla okukhupha ama-joints kunye nokwenza inkqubo yokucubungula ilula. Nangona kunjalo, kukwakho izinto ezingeloncedo. Ukusetyenziswa kokuwelda kweplasma kubavelisi bezixhobo zokubopha iingcingo kufuna izixhobo zokuwelda zeplasma ezizinikeleyo, ezinokuguquguquka okubi kunye nokwandisa utyalo-mali kwii-asethi ezisisigxina zabavelisi beentambo zokubopha. Okwesibini, kwinkqubo ye-plasma welding, i-solder igqitywe ngesenzo se-capillary. Inkqubo yokuzaliswa kwe-gap kwindawo ye-crimping ayilawuleki, okubangelwa umgangatho ongazinzanga we-welding ekugqibeleni kwindawo yokudibanisa i-plasma welding, okubangelwa ukuphambuka okukhulu ekusebenzeni kombane kunye noomatshini.

Ixesha lokuposa: Feb-19-2024